IVEMA-PRESS

Stainless steel NOTCH connector | …for handpress-tools!!!

Usually there are no bad issues by crimping rope-connections of Bronze-ropes, pure copper-ropes, or steelcopper-alloy ropes. Everyone uses oval-crimp connectors made of copper.

These material combinations are, of course, optimal!

But completely different is the crimping of stainless steel ropes or hot-dip-galvanized ropes (zinc-plated). Recently a numerous of companies (e.g. Catenary-installers, and Tram-operators as well) asking themselves the serious question:

“how do I really crimp stainless steel ropes – technically flawless!?”

Latest after some press-connections became loose, it reveals that the common combination of stainless ropes with Aluminum-notch connectors is a really bad decision.

After some years a worst Alu-corrosion and oxidation will takes place and partly the oval-notch-connectors will become loose.

That´s why we know that this topic has to be taken with highest seriousity!

Under this technical background it is self-explanatory the aluminium/ stainless crimping should´nt be used anymore, whereas the crimp connectors made out of stainless steel can and shall be used for the future.

Basicly notchconnectors made of stainless steel are available in the market, BUT: the point is these connectors are only available with mantle thickness of 3 mm so far. This fact causes problems by pressing with a manual handpress tool at the crafting site, which is impossible by the high crimp-pressures needed! (thick notch-connectors need a press force of 200 kN and more)

Ivema´s team has researched this issue and has with a numerous of material- and crimptests developed a crimp connector that has a relative thin mantle and thus opens the possibility to crimp with a manual pressing tool – Ivemapress just requires 130 kN press force, only.

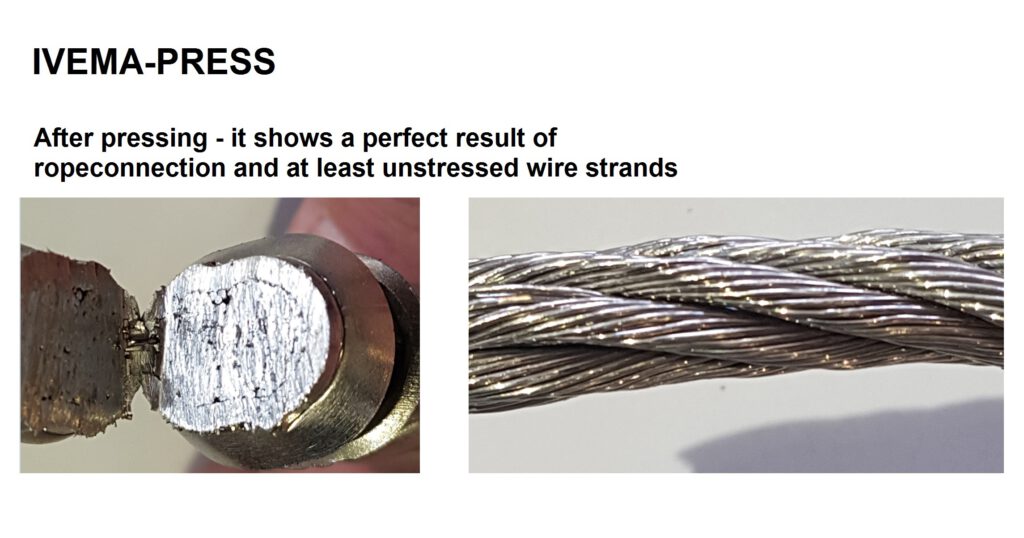

These mentioned 130 kN press force that needs to be applied on our new IVEMA-PRESS notch connector leads to a flawless compression of the oval-connectors <-> stainless-steel-ropes.

It also leads to a very well material-connection and deforming inside the connector and won´t stress the steel wire strands. (as you see in the following depiction below)

Please! …be aware of our technical rights for this product. Patent pending.